INDUSTRIAL PACKAGING

FIBC Bag Types

What’s the right type of fabric and construction of your FIBC bag?

When using FIBC bags for shipping, your products will rub up against the fabric during filling, moving, and emptying. This creates static electricity which can cause problems and can be dangerous. Choosing the right material and construction for your application is essential.

Choosing Type A, B, C, or D Bulk Bags

| MIE (Minimum Ignition Energy) of Dust | Non-Flammable Environment | Explosive Dust Environment | Explosive Gas & Vapor Environment |

| MIE > 1,000 mJ (milliJoules) | A, B, C, D | B, C*, D | C*, D |

| 1,000 mJ ≥ MIE > 3 mJ | B, C, D | B, C*, D | C*, D |

| MIE ≤ 3 mJ | C, D | C*, D | C*, D |

*ONLY IF GROUNDED

Type A Bags

Type A FIBCs are made of plain-woven polypropylene and other non-conductive fabrics. There is no static protection provided by Type A FIBCs. Use Type A bulk bags to transport non-flammable products safely. There should not be any flammable solvents or gases present around a Type A FIBC.

When to use type A bulk bags:

- When transporting non-flammable products

- When no flammable solvents or gases are present around the bag

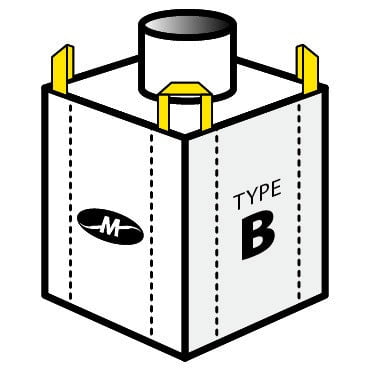

Type B Bags

Like Type A FIBCs, Type B bags are made of plain-woven polypropylene and other non-conductive fabrics. They provide no static protection. The difference between Type B and Type A bags is that Type B bags use materials that have a low breakdown voltage. This prevents propagating brush discharges. They are not considered anti-static bulk bags because they do not dispel electrostatic charges.

When to use type B bulk bags:

- When transporting non-flammable powders

- When no flammable solvents or gases are present around the bag

- When used in environments with dust with ignition energies less than 3mJ

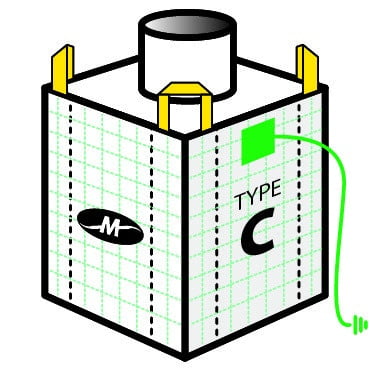

Type C Bags

Type C FIBCs, conductive FIBCs, or ground-able FIBCs, are made from non-conductive polypropylene fabrics interwoven with conducting filaments sewn into the fabric. The conducting threads are connected to a designated ground during filling and discharging.

When to use type C bulk bags:

- When transporting flammable powders

- When flammable vapors, gases, or combustible dust is present

When not to use type C bulk bags:

- DO NOT USE when ground connection is not present or has become damaged.

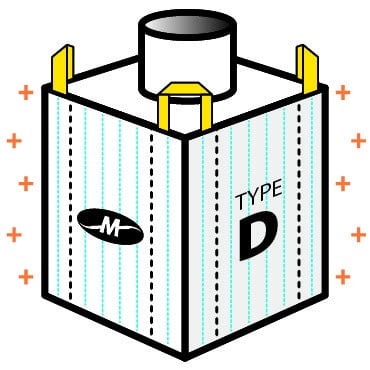

Type D Bags

Type D FIBCs are made from antistatic and static dissipative fabrics. This prevents the occurrence of incendiary sparks, brush discharges and propagating brush discharges. There is no need for a connection from the FIBC to a designated ground/earth.

When to use type D bulk bags:

- When transporting flammable powders

- When flammable vapors, gases, or combustible dusts are present

When not to use type D bulk bags:

- DO NOT USE type D FIBCs when the bag surface is contaminated or covered with conductive materials, such as water or grease.

Request a Quote

Have one of the specialists at Material Motion contact you to find the right solution for your packaging needs!